Product List

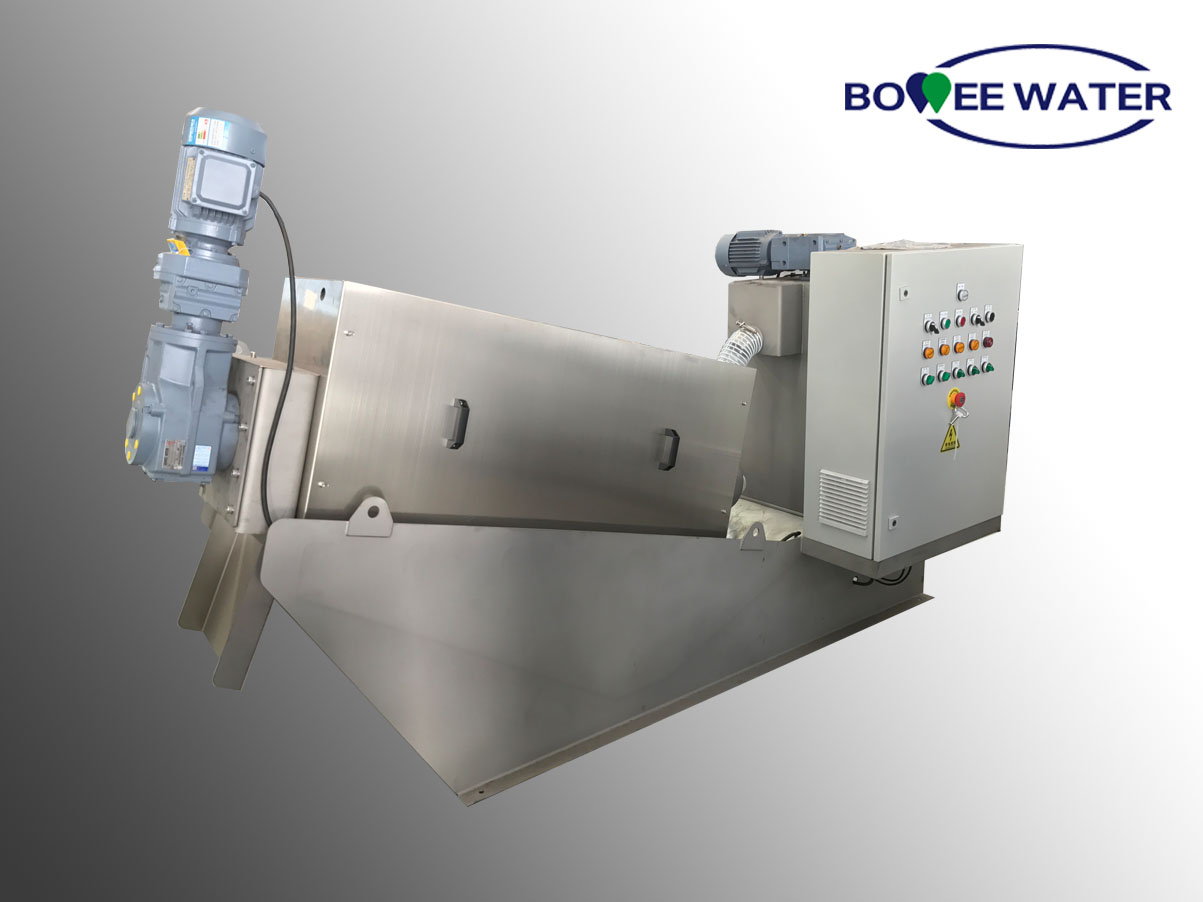

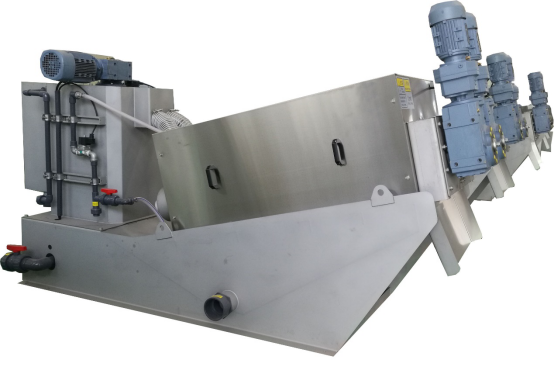

Dewatering screw press is used for efficient thickening and dewatering of sludge waters. Sludge waters are water, containing certain amount of suspended solids, these can be product of waste water treatment, food proccessing industry, chemical industry and other branches of human activity.

Specifcations:

Dimension: Customized

Capacity:6-600kg DS/h

Material:SS304 or SS316

Motor:First-class motor, Nord or SEW is optional

-

Description

Dewatering screw press is used for efficient thickening and dewatering of sludge waters. Sludge waters are water, containing certain amount of suspended solids, these can be product of waste water treatment, food proccessing industry, chemical industry and other branches of human activity. Our dewatering screw press, which serves to thicken sludge water to 20% dry-matter content on municipal sludges and more for mineral/industrial sludges, can provide efficient desludging. In terms of quality, this equipment surpasses traditional sedimentation sludge removal and other technologies.

This dewatering/thickening screw press has been designed to be used primarily in wastewater treatment plants, but can also be used for thickening both industrial water and wastewater in food-processing operations

If a dewatering press is already incorporated into the new WWTP design, costs related to the construction of sedimentation tanks are eliminated as this equipment can also be used for thickening secondary sludge directly from activation.

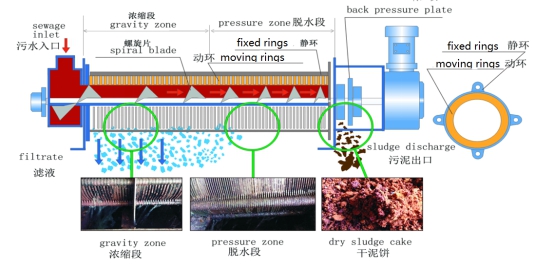

Principle:

Gravity zone: When the shaft is driven by the screw, moving rings around the shaft move up and down relatively. Most water is pressed out from the thickening zone and fall down to the filtrate tank for gravity.

Pressure zone: The thickened sludge moves forward continuously from the gravity zone towards the pressure zone. With the pitch of the screw shaft thread getting narrower and narrower, the pressure in the filter chamber increases higher and higher.

In addition to the pressure generated by the back-pressure plate, the sludge is greatly pressed and dryer sludge cakes produce.

Structure:

-

Applications

Dewatering screw press could be used in the treatment of industrial wastewater, surface water, reused water, drinking water plant and Municipal Wastewater Treatment Plant.

-

Technical parameters

Main Specifications

Design Parameter

Capability

10-480kgds/h

Total Power

0.36-6kw

Protection Grade

Protection Grade: IP55

Insulation Grade: FPower Supply

According to actual usage

Output Moisture Content

75-85%

Polymer Feeding Rate

DS 0.2~1%

Screw Body

Quantity

1-3

Material

Plate: SUS304

Screw Shaft: SUS304Flocculation Mixing tank

Volume

40-1500L

Material

SUS304

Components Brand

Screw Reducer

GUOMAO/SEW/NORD

Mixing Reducer

GUOMAO/SEW/NORD

Liquid Level Switch

Omron

Solenoid Valve

ASCO

Frequency converter

Schneider

Model

Dry Solids Capacity

Dimension

Weight

Motor Power

(Kg-DS/hr)

(mm)

(Kg)

(Kw)

(L)

(W)

(H)

Net

Operating

Total

BWSP-131

6-10

1860

740

1075

185

310

0.2

BWSP-132

12-20

1960

870

1075

350

480

0.3

BWSP-201

9-15

2650

750

1380

420

540

0.74

BWSP-202

18-30

2650

940

1380

550

660

1.11

BWSP-203

27-45

2650

1190

1380

700

1010

1.48

BWSP-301

50-70

3200

1100

1600

775

1300

1.5

BWSP-302

60-100

3640

1260

1825

1350

2000

2.25

BWSP-303

90-150

3900

1620

1825

1900

2700

3

BWSP-304

120-200

3900

2040

1825

2500

3800

3.75

BWSP-351

60-120

3900

1260

2190

2210

3500

1.85

BWSP-352

120-240

4240

1620

2190

3400

5250

2.95

BWSP-353

180-360

4460

2040

2190

4850

6600

4.05

BWSP-354

240-480

4660

2650

2190

6100

7700

5.15

BWSP-401

90-150

4350

1020

2160

2200

4700

1.85

BWSP-402

180-300

4350

1550

2160

3500

5800

2.95

BWSP-403

270-450

4570

2100

2160

5500

6900

4.05

BWSP-404

360-600

4570

2650

2160

7000

9500

5.15

-

Advantages

1. Automatic continuous operation

2. Compact design with flocculation and dewatering

3. Low power and water consumption

4. Low operation cost

5. No filter cloth, no clogging

6. No need for sludge thickener

7. Easy operation and maintenance

8. No vibration and noise

-

Related Products